Be Energy South Africa

Our services

A second life for your batteries: an ecological and economic choice

Be Energy’s regeneration and maintenance services

Service delivery – battery regeneration

Do you have one or more batteries to regenerate? We take care of their regeneration using our cutting-edge technologies, specially designed to dissolve lead sulfate crystals and restore the efficiency of the batteries.

The steps of regeneration

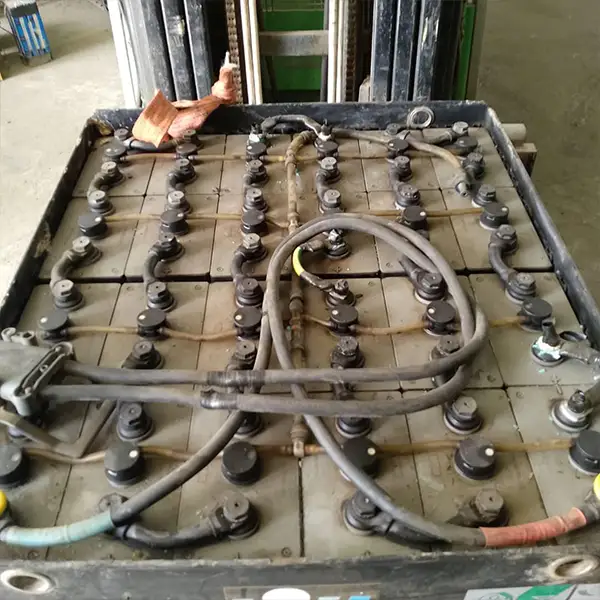

- Battery cleaning

- Battery inspection

- Voltage and density measurement

- Full discharge of the battery

- Battery regeneration

- New compliance discharge

- New voltage and density measurement

- The battery is regenerated and ready for the same use.

The benefits of regenerating your batteries

CSR

CSR 50 to 70 times less carbon-intensive

50 to 70 times less carbon-intensive 2 times less hazardous waste

2 times less hazardous waste Preserves resources Circular economy

Preserves resources Circular economyMaintenance contract for your batteries

We offer a tailored maintenance contract for businesses with their own fleet of handling equipment. This contract includes regular maintenance and regeneration of your batteries, ensuring their optimal performance and longevity.

The maintenance offer in detail

- Several interventions per year (13 inspection points)

- Preventive regeneration on-site

- Corrective regeneration in the workshop

- Supplies (sets of connectors, sets of caps, sulfuric acid containers, etc.)

The benefits of the maintenance contract

The benefits of the maintenance contract

Be Energy’s regeneration process

The Be Energy regeneration process effectively removes lead sulfate crystals without the need to open the battery. By leveraging high-power electrical pulses, our Made-in-France technology efficiently dissolves these deposits, restoring battery performance. Delivering results 8 to 10 times more effective than conventional methods, we provide an innovative and sustainable solution to significantly extend the lifespan of your batteries.

Contact us

News

Interview Mr Brian Oxenham CEO D’Oxenham

Why did you choose Be-Energy for your Regenerations? When Kersley and Jean-Michel first came to see me, they presented...

Telephone operator EMTEL is switching to regeneration

On May 29, 1989, Emtel became the first private cell phone operator in Mauritius. A subsidiary of the Currimjee group,...

Be Energy Mauritius: sustainable solutions to the waste problem in Mauritius

In October 2023, Be Energy Mauritiusjoined the Be Energy network and benefited from on-site training, designed to make...

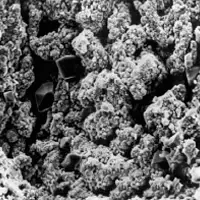

Sulfated

battery

The lead sulfate crystals that form on the surface of the electrodes gradually reduce the battery’s capacity, hindering its ability to hold and deliver charge efficiently.

The BRT20 Maxi Gold Be Energy emits an ultra-powerful electrical signal that converts into a mechanical shock, effectively breaking down lead sulfate crystals in the electrolyte, restoring battery efficiency and prolonging its lifespan.

Desulfated battery

After regeneration, the solid lead sulfate masses dissolve back into the electrolyte, restoring the battery’s capacity and improving its overall performance.

Before

After

A battery restored to like-new condition

The battery regeneration process starts with a thorough cleaning of the received battery. Any damaged components, such as cables, caps, or other defective parts, are carefully replaced.

Next, the battery is refilled with fresh acid before undergoing the regeneration process, which dissolves lead sulfate buildup and restores its capacity. Rigorous performance tests are then conducted to ensure optimal functionality.

The result : a revitalized battery with performance comparable to a new one, ready to be used efficiently and reliably.

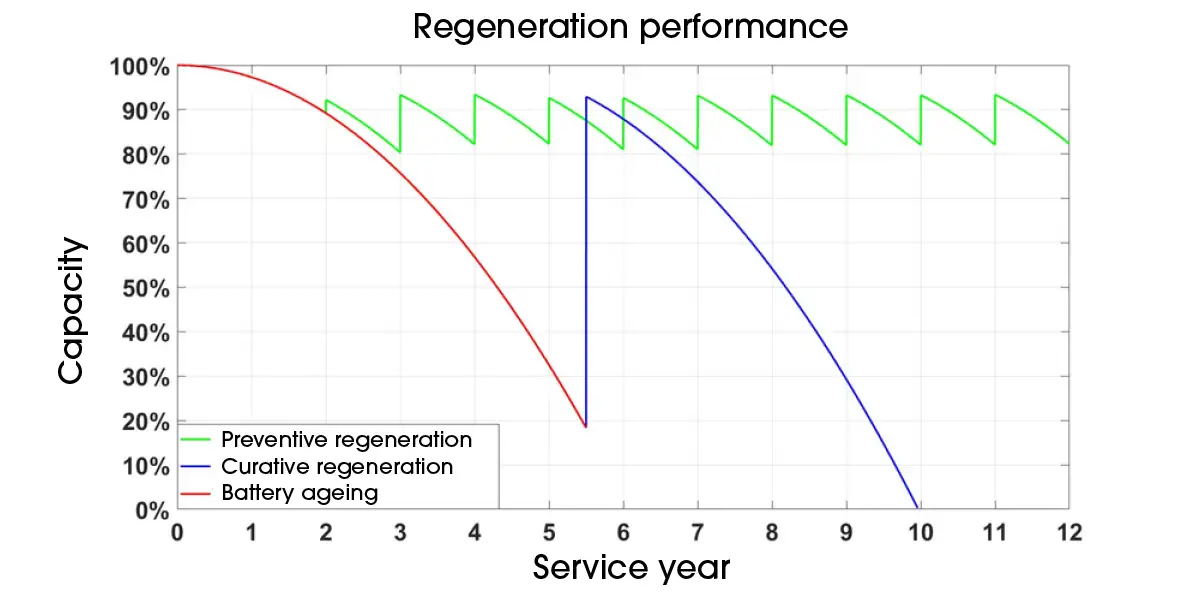

Preventive regeneration vs. corrective regeneration

Preventive regeneration is carried out before significant battery degradation occurs, proactively optimizing both lifespan and performance. This approach helps maintain efficiency and prevent premature wear.

In contrast, corrective regeneration is applied to already degraded batteries, aiming to restore their functionality. However, this process is often less effective and more complex, as the damage may be extensive.

By prioritizing preventive regeneration, businesses can better preserve their equipment, reduce long-term costs, and ensure more reliable battery performance.